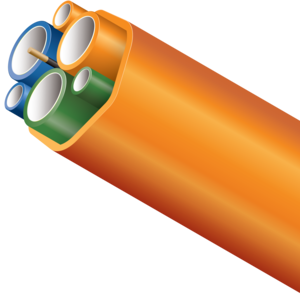

For this reason, many operators are aiming to underground half of their distribution by 2040. While there are many materials to choose from to protect your infrastructure underground, high-density polyethylene’s (HDPE) unique properties offer exceptional protection as well as more streamlined installations.

1: Multiple Formats Save You Time and Money

Just like PVC, HDPE is available in sticks, but the material properties of HDPE allow it to be extruded in long, continuous lengths. Because it can be wound and transported on reels or in coils, you’ll also save on transportation and storage costs.

Long, continuous lengths of HDPE can also offer you a drastic reduction in time and money spent on coupling. HDPE can even be supplied with pre-installed cable (Cable-in-Conduit, or CIC) to eliminate another installation step.

2: Enables Trenchless Technologies

While traditional open trenching is still possible with HDPE, it’s ideal for installation via trenchless methods—like horizontal directional drilling (HDD)—that can save you money and overcome challenges in terrain or existing infrastructure. HDPE on reels or in coils makes it easy to install extensive sections on conduit in a single step, without digging a large trench and then laying and coupling individual sticks of conduit.

And even if you’re installing HDPE sticks, trenchless methods are still possible with fusion welding, which creates joints between individual sections of pipe as strong as the conduit itself and able to withstand the tensile loads required for HDD.

3: Flexibility for Any Terrain

HDPE is naturally more flexible and ductile than other conduit materials, which can allow for more streamlined undergrounding:

- Bends without breaking in cold temperatures and challenging terrains

- Maneuverable without heating, and can accommodate gradual changes in direction or elevation along your route without preformed fittings.

Although HDPE sweeps are available for more pronounced changes, HDPE’s natural flexibility can translate into time and cost savings through faster installations and simpler inventory management.

4: Versatile Coupling Options For Safer, Faster, and Stronger Installations

HDPE couplers can be installed by hand with no need for messy (and potentially toxic) glue, cement, or primer. Installers can work safely and without risk of polluting soil or water, and lay the coupled conduit into the trench as soon as the coupler is installed—no need to wait for adhesives to dry.

Mechanical couplers allow for an air- and watertight connection between two lengths of conduit, and some can join HDPE to other conduit materials for even greater versatility.

And if your installation demands it, HDPE is also compatible with fusion coupling methods like electrofusion and butt fusion, both of which create strong joints and eliminate the need for a separate coupler.

-x.png?version=1718024029)